WHAT DOES WEAR MEAN?

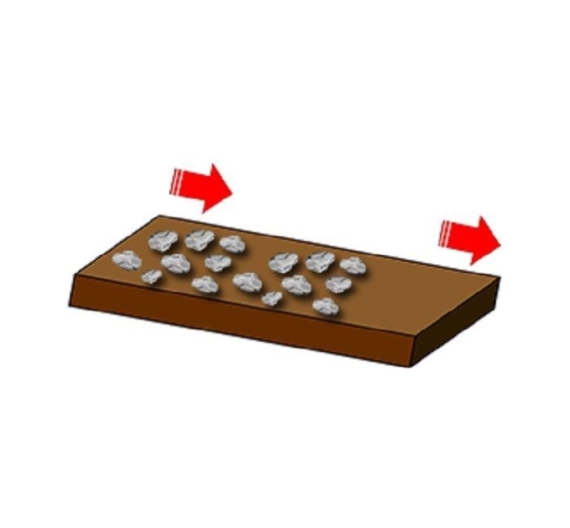

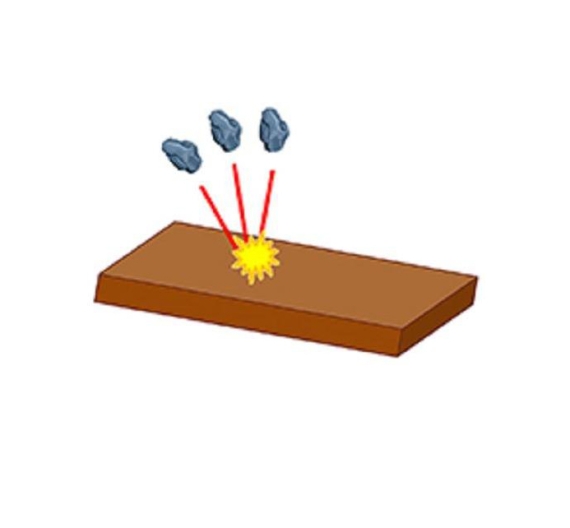

We know that wear is a phenomenon which results in damage to the surface of two solid bodies which are in contact and in relative motion. There are various kinds of mechanisms involved in this phenomenology, but the one which effects the production of our plants most is one of the quickest and severest forms of wear and tear – abrasion.

By abrasion we mean the damage caused to a plate by the passage of particles of a material which are as hard as / harder than the plate surface itself, and this can have several results, each with its own characteristics.

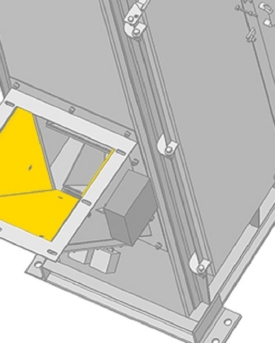

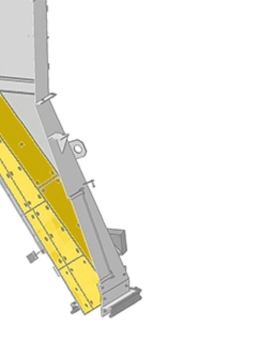

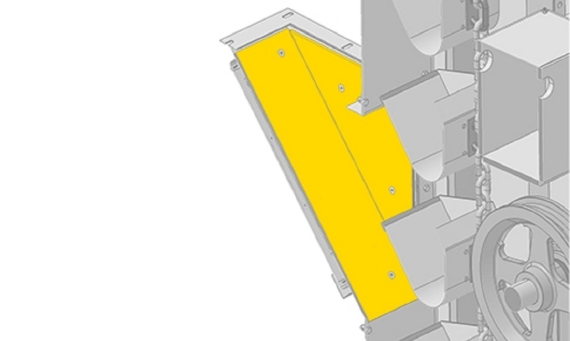

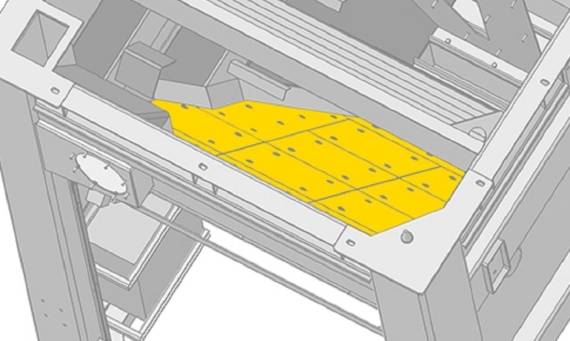

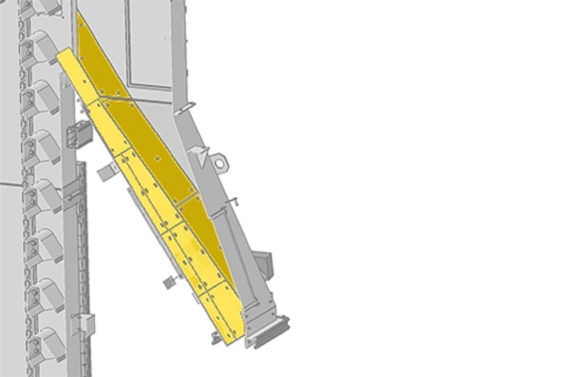

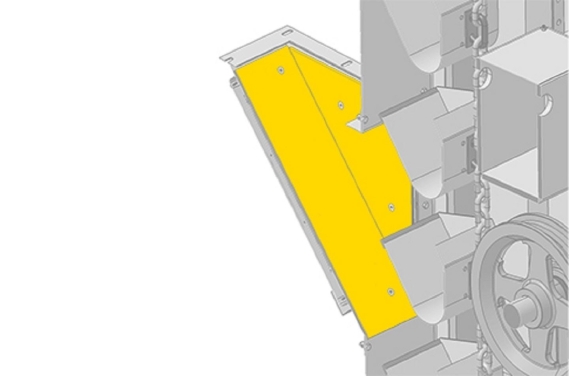

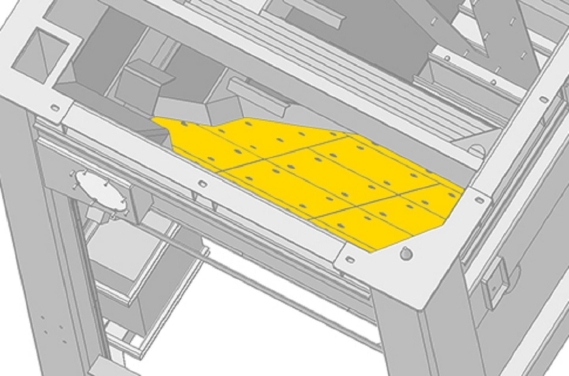

PLANT PARTS SUBJECT TO WEAR

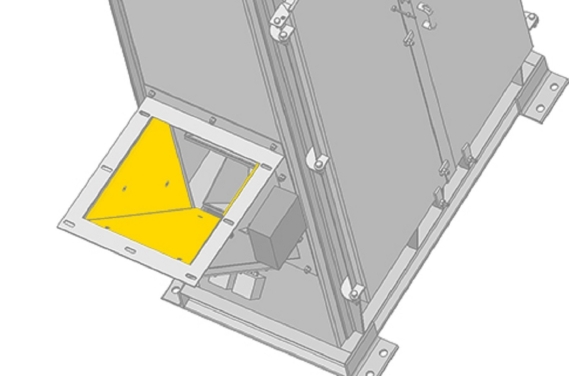

Thanks to 30 years experience and constant dialogue with our clients, MARINI technicians are aware that the parts which are most frequently subject to abrasion and require greater intervention and maintenance are the material discharge chutes, in addition to the central core element of the plant – the mixer. These plant parts are generally lined with HARDOX. However, when conditions deteriorate, we advise our clients to use MARINI ENDURANCE.

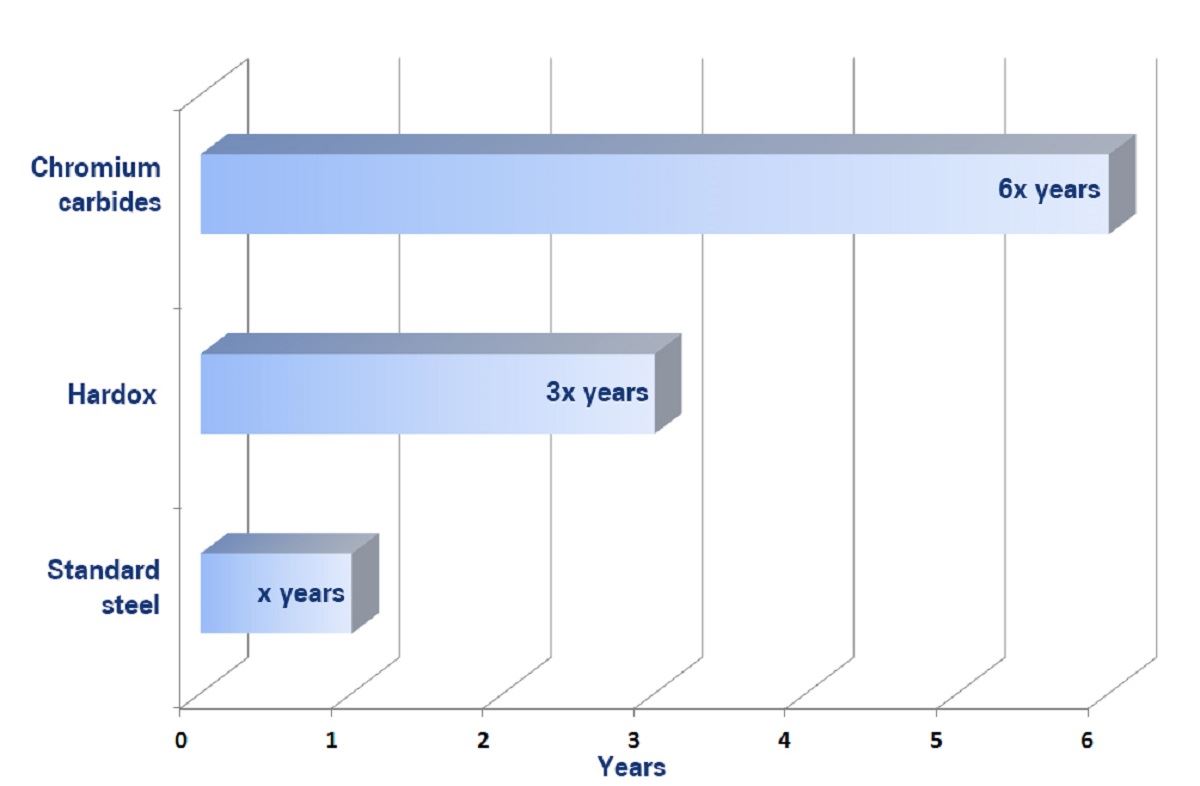

Vickers chromium carbide hardness, compared with various minerals

What is ENDURANCE MARINI ?

MARINI ENDURANCE consists of carbon sheet plates soldered with a high-density chromium carbide alloy lining, which increases resistance to abrasion, even at high temperatures, without effecting the flow of materials and the costs.

THIS SOLUTION IS AN ADVANTAGE FOR ALL PLANTS AND BECOMES AN ABSOLUTE MUST FOR WHOEVER NEEDS TO WORK UNDER THE FOLLOWING CONDITIONS:

- with hard materials with a shape that can cause high levels of wear and tear

(e.g. basalt materials)

- with RAP

especially when the exact nature and shape of the material is not known and which could be highly abrasive. In order to encourage the flow of the material, the chutes are usually heated, and it is known that high temperatures can have a negative effect on the hardness of the material. For this reason if RAP is used in the recycling ring, MARINI fits out the plant with a complete kit of resistances to heat the discharge chutes, together with MARINI ENDURANCE plates.

The plates have holes for quick and easy assembly and replacement with bolts. It is therefore possible to purchase the kit right at the beginning of the plant’s life, or it can be installed at a later date during retrofitting procedures.

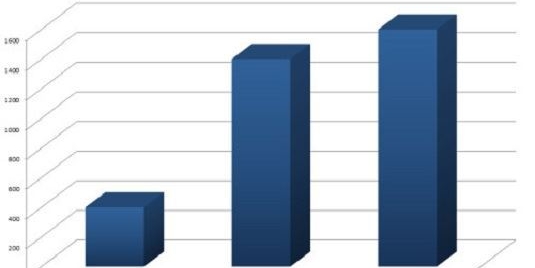

Lifetime in years

EXAMPLES OF POSSIBLE APPLICATIONS