XPRESS

READY FOR ACTION

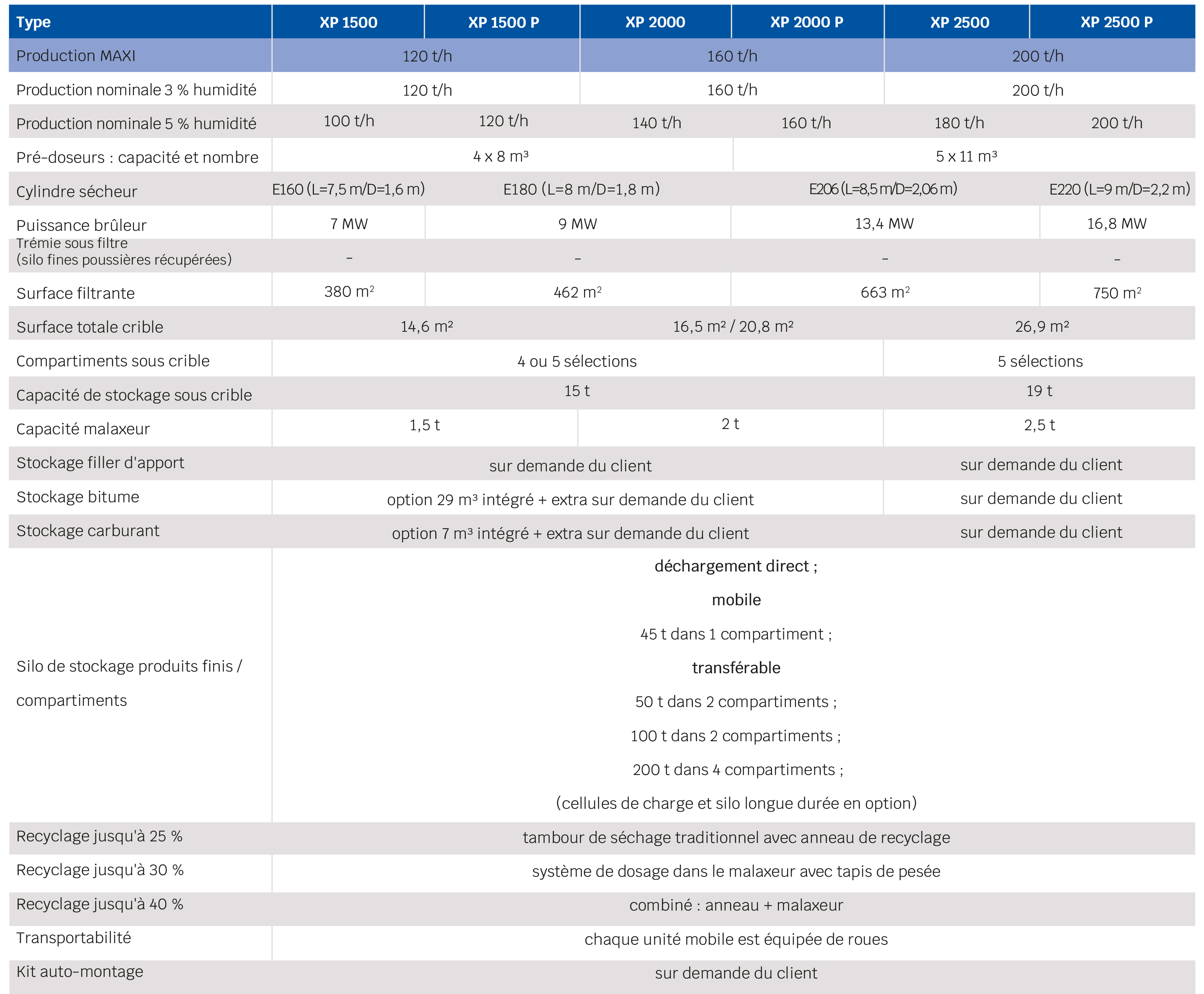

The range: XP 2000 (160 t/h), XP 2500 (200 t/h) | RAP: 40 %| Assembly/Transport: mobile | Main features: 1 dryer drum, 1 burner

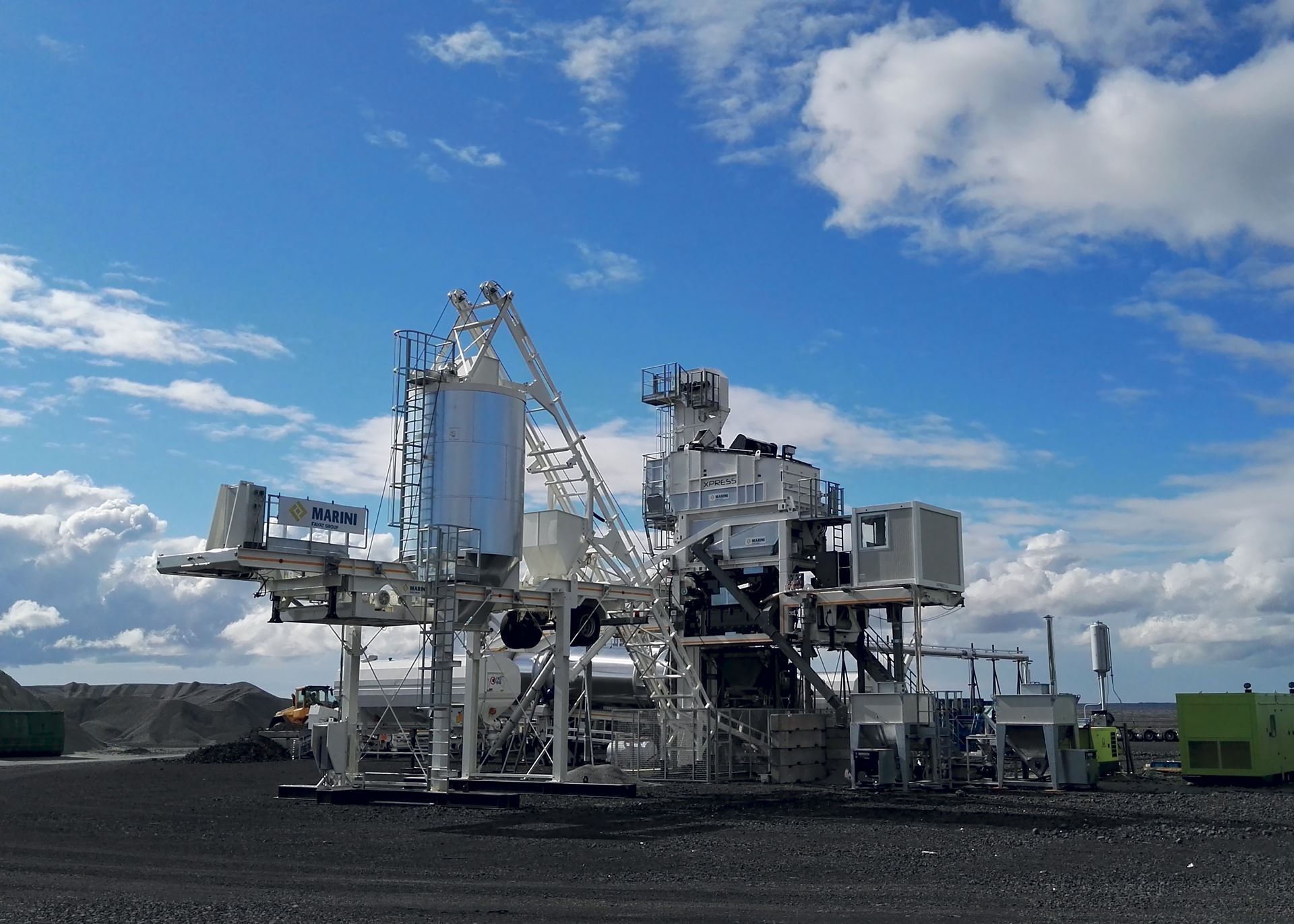

XPRESS is a mobile batch plant with an output of up to 200 t/h. It’s wheel-mounted for easy transport and suitable for short-term, itinerant production sites or logistically difficult ones.

Whatever your site challenges may be, XPRESS gives you the best in terms of cost/performance.

MAIN CHARACTERISTICS: ready to produce with no delay, impianto flessibile, moderno e mobile

XPRESS: READY TO PRODUCE WITH NO DELAY

Whatever the location and whatever the number of working sites, if you are looking for a modern, flexible, itinerant plant go no further, MARINI has the plant for you.

With XPRESS you get practical transport of plant components without exceeding road transport dimensions, in record time and with no road escort. XPRESS can be erected and dismantled quickly with the aid of a small crane, without effecting the quality of operations and making considerable savings.

3, 2, 1… GO!

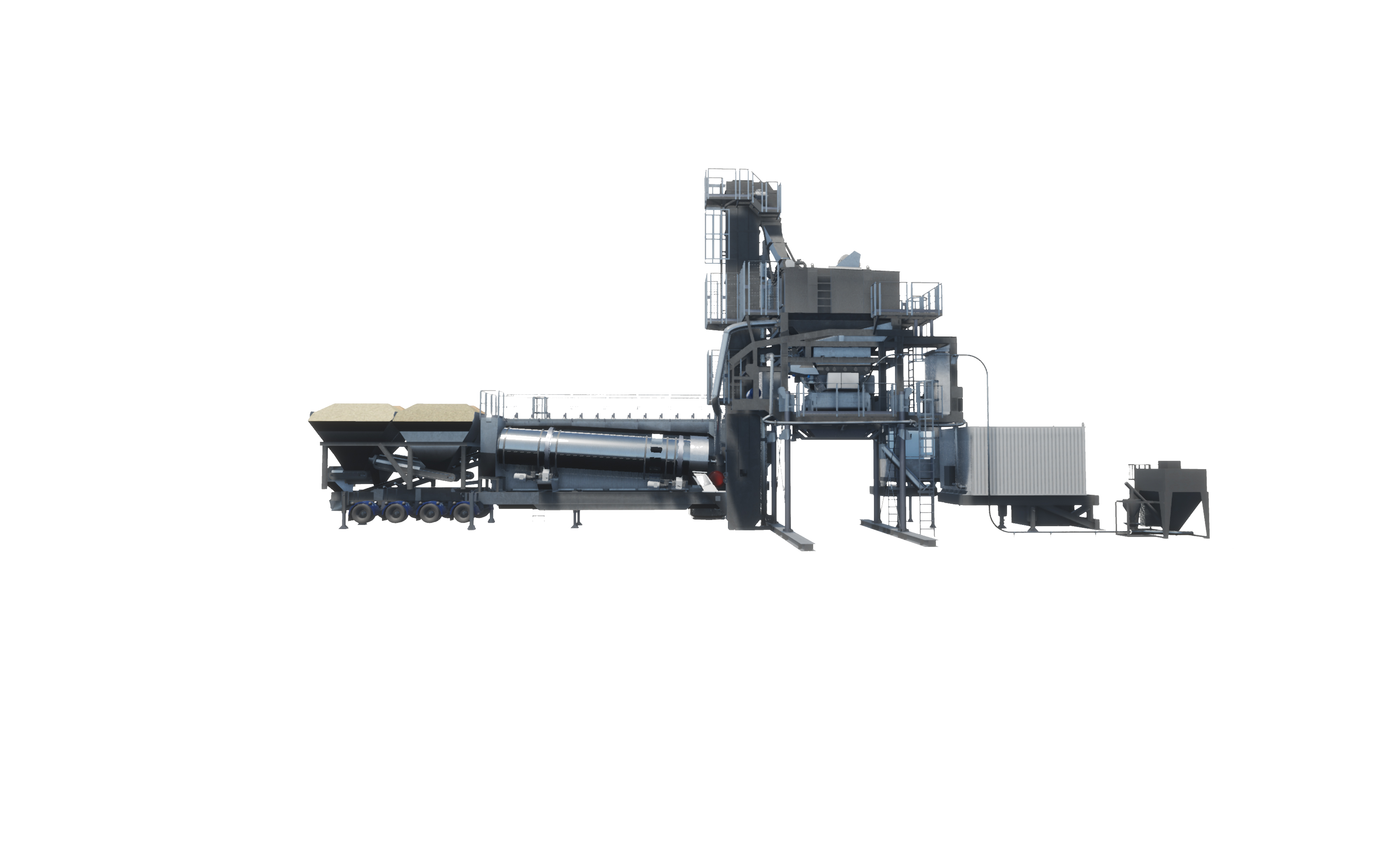

Erection operations are just like a real and proper transformation of the main plant trailer.

- The screen is electrically transported to the top of the tower

- The main trailer is hydraulically lifted

- The elevator is turned to reach the final position

- A sequence of user-friendly operations and the self-erection kit cuts out the necessity of using third parties to complete the installation.

- Ample access spaces are provided throughout the plant to ensure better safety and rapidity of all maintenance operations.

FULL OPTIONALS AND HIGH QUALITY LEVEL : Flexibility is an absolute priority for MARINI. In addition to a system for producing foam bitumen when producing WMA at low temperatures, XPRESS can be fitted with a series of optionals, ranging from the traditional MARINI recycling ring to a cold recycling solution in the mixer. Thanks to this new innovative design, considerably high levels of recycling can be achieved, both from the environment-friendly and cost-friendly points of view – using from 25% to 40% RAP in certain cases.

MARINI combines technology and experience to achieve quality and reliability in all its component parts. XPRESS can be fitted with special MARINI ENDURANCE anti-wear plates, which can resist abrasion for up to 6 times more than plates made from traditional material.